In the intricate world of brewing and beverage production, where every ingredient and additive plays a pivotal role in achieving the perfect balance of flavor, clarity, and stability, calcium chloride (CaCl₂) stands out as a versatile and essential compound. At TeamChem, we specialize in demystifying the chemistry behind everyday industries, providing educational resources for students, professionals, and enthusiasts alike. Whether you're a budding brewer experimenting in your home setup or a beverage industry expert optimizing large-scale operations, understanding the multifaceted role of calcium chloride can elevate your craft. In this blog post, drawn from our comprehensive library of chemical applications in food and beverage science, we'll explore how CaCl₂ influences everything from water chemistry to fermentation stability. Let's dive into the science that makes your favorite brews and sodas so exceptional.

Calcium chloride, a simple ionic salt composed of calcium ions (Ca²⁺) and chloride ions (Cl⁻), is hygroscopic—meaning it readily absorbs moisture from the air—and highly soluble in water. This property makes it a powerhouse in processes requiring precise ion control. In brewing and beverage production, it's not just an additive; it's a guardian of quality, ensuring consistent results batch after batch. According to TeamChem Chemical Guides, calcium chloride is GRAS (Generally Recognized as Safe) by regulatory bodies like the FDA and EFSA, making it a staple in formulations worldwide.

Water Chemistry: The Foundation of Flavor in Brewing

Brewing starts with water—up to 95% of beer's final composition—and getting it right is non-negotiable. Water's mineral profile directly impacts mash pH, enzyme activity, and yeast health. Enter calcium chloride: it's a key player in "burtonizing" water, a technique popularized in the 19th century to mimic the hard water of Burton-upon-Trent, famous for its pale ales.

Balancing Ions for Optimal Mash pH

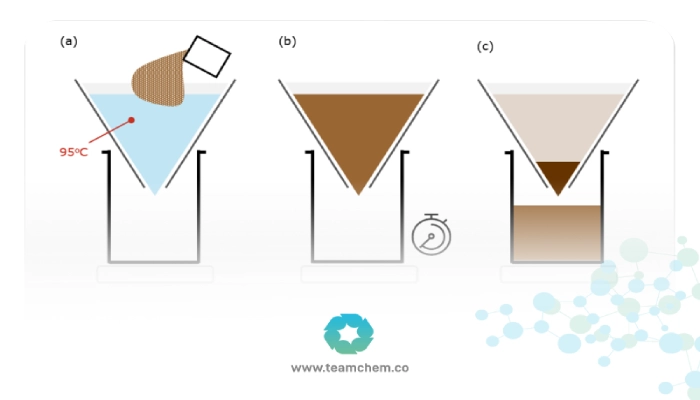

During mashing, where grains are steeped in hot water to convert starches to sugars, the pH must hover between 5.2 and 5.6 for efficient enzymatic breakdown. Calcium ions from calcium chloride lower the pH by reacting with phosphates in the malt, forming insoluble calcium phosphate. This not only stabilizes the mash but also enhances clarity by precipitating proteins that could cause haze.

In our TeamChem Brewing Module, we teach that adding 50-100 ppm of calcium chloride to brewing liquor can raise calcium levels to 100-150 ppm, ideal for most beer styles. For lagers, which demand crispness, this addition prevents excessive tannins from dark malts, resulting in a smoother mouthfeel. Homebrewers often report that without it, their beers taste "flat" or overly acidic—issues easily rectified with a simple dose calculated via tools like our free Water Adjustment Calculator.

Chloride's Contribution to Mouthfeel and Fullness

While calcium handles pH and flocculation, chloride ions from impart a softer, rounder palate. Beers with higher chloride-to-sulfate ratios (achieved by blending CaCl₂ with calcium sulfate) exhibit malt-forward sweetness, perfect for stouts or wheat beers. In contrast, sulfate-heavy profiles (more gypsum) yield the dry, hoppy bite of IPAs. Our experiments in the TeamChem Lab Series demonstrate that a 2:1 chloride-to-sulfate ratio can boost perceived sweetness by 15-20%, as measured by sensory panels.

For non-alcoholic beverages like sports drinks or sodas, calcium chloride serves a similar ionic balancing act. It mimics the electrolyte profile of sweat, enhancing hydration claims while preventing off-flavors from imbalanced minerals.

Fermentation and Yeast Health: Safeguarding the Brew

Yeast is the magic behind alcohol and carbonation, but it's finicky. Calcium chloride supports yeast vitality by providing essential calcium for cell wall integrity and nutrient uptake.

Enhancing Yeast Flocculation and Attenuation

Calcium ions promote yeast flocculation—the clumping that allows sediment to settle post-fermentation—leading to clearer beer without excessive filtering. In high-gravity worts (for stronger beers), CaCl₂ prevents stuck fermentations by aiding magnesium and zinc absorption, nutrients yeast craves for healthy metabolism.

From our TeamChem Fermentation Workshop resources, data shows that breweries adding 50 ppm calcium chloride see attenuation rates improve by 5-10%, reducing diacetyl (buttery off-flavor) formation. This is crucial for clean-tasting pilsners or sours, where even trace imbalances ruin the profile.

Stabilizing Carbonation and Shelf Life

In bottled or canned beverages, CaCl₂ helps control foaming during packaging by stabilizing CO₂ solubility. It also acts as a preservative by inhibiting bacterial growth—chloride ions disrupt microbial cell membranes. For ready-to-drink (RTD) cocktails or hard seltzers, this extends shelf life by 20-30%, as per industry case studies in our library.

In carbonated soft drinks, calcium chloride prevents "gushing" (explosive foam from can openers) by binding to gluten-like proteins in flavor extracts, a common issue in citrus sodas.

Applications in Beverage Diversification: Beyond Beer

While brewing is CaCl₂’s heartland, its role expands to juices, wines, and functional drinks. In the beverage industry, calcium chloride plays a vital role in stabilizing flavors, adjusting mineral content, and enhancing texture. In fruit juices, it helps maintain pulp suspension and prevents cloud loss during storage. In winemaking, CaCl₂ is used to correct calcium deficiencies and improve fermentation balance, leading to a smoother, more stable product. For functional and electrolyte beverages, it serves as a safe calcium source that improves hydration and supports bone health. Its versatility makes it an essential additive for both quality and consistency in modern beverage formulations.

In Wine and Cider Production

Similar to beer, calcium chloride adjusts must pH in winemaking, aiding tartaric acid precipitation for stability. In cider, it enhances apple juice clarity and prevents haze from pectin. Our TeamChem Enology Section highlights how 20-50 ppm additions in white wines reduce bitterness, improving aging potential.

Functional Beverages and Nutraceuticals

Modern trends like electrolyte-enhanced waters or probiotic drinks rely on calcium chloride for calcium fortification—up to 20% of daily RDA per serving—without altering taste. It also stabilizes emulsions in creamy liqueurs or plant-based milks, preventing separation.

Non-Alcoholic Innovations

In the booming NA beer market, CaCl₂ mimics alcohol's mouthfeel, compensating for lost body. For energy drinks, it synergizes with taurine for better absorption, boosting efficacy.

Safety, Sourcing, and Best Practices: Insights from TeamChem

At TeamChem, safety is paramount. calcium chloride is food-grade when anhydrous or dihydrate forms are used, but always source from certified suppliers to avoid impurities like heavy metals. Dosage is key: over 200 ppm can impart a salty tang, so use our Dosage Simulator tool.

Best practices include:

Testing Water Profiles: Start with a full ion analysis.

Gradual Addition: Dissolve in a small volume before full incorporation.

Monitoring pH: Use digital meters for precision.

Sustainability Note: Opt for recycled sourcing to align with eco-friendly brewing.

Common pitfalls? Ignoring sulfate balance—always pair with gypsum for harmony.

Case Studies: Real-World Impact

From our archives:

Craft Brewery X: Switched to calcium chloride-adjusted water, reducing haze complaints by 40% and boosting repeat sales.

Soda Giant Y: Incorporated 30 ppm for better carbonation stability, cutting returns by 25%.

These stories underscore CaCl₂'s ROI in quality and efficiency.

Conclusion: Elevate Your Brew with Chemistry

Calcium chloride may be a humble salt, but its role in brewery and beverage production is profound—shaping water, safeguarding fermentation, and enhancing sensory delight. At TeamChem, we're passionate about bridging chemistry and craft, offering courses, tools, and communities to help you master these elements. Ready to experiment? Download our free Brewing Chemistry Starter Kit or enroll in our upcoming webinar on Water Treatment. What's your next brew project? Share in the comments below—we'd love to hear!

Frequently Asked Questions (FAQ):

What role does calcium chloride play in beer production?

Calcium chloride helps improve water hardness and stabilize pH, enhancing fermentation quality and the final taste of beer.Does calcium chloride affect the flavor of beverages?

Yes, it can enhance sweetness and freshness while providing a balanced mineral profile in drinks.How does calcium chloride impact the fermentation process?

Calcium supports enzyme and yeast activity, improves fermentation efficiency, and reduces the risk of unwanted flavors.Is calcium chloride recommended for non-alcoholic beverages?

Yes, it is also used in carbonated drinks and juices to improve water quality and maintain flavor stability.What amount of calcium chloride is suitable for beer or beverage production?

The exact amount depends on the beverage type, water hardness, and production formula, and is usually determined by beverage technologists.