In the dynamic world of industrial chemistry, Monoethanolamine (MEA), also known as mono ethanol amine mea, stands out as a versatile compound essential for applications ranging from gas treatment to personal care products. At TeamChem, a leading supplier of high-purity industrial chemicals, we prioritize safety as the cornerstone of our operations. With over two decades of experience delivering reliable solutions to sectors like oil and gas, pharmaceuticals, and manufacturing, we understand the critical need for robust safety protocols when handling substances like MEA. This comprehensive guide, spanning more than 2800 words, delves into the safety guidelines and handling precautions for MEA, drawing from globally recognized standards such as OSHA, GHS, and NFPA. Whether you're a technician in a refinery or a lab professional, these insights will empower you to mitigate risks effectively. At TeamChem, we not only supply MEA but also offer tailored safety training and compliance consulting to ensure your team's protection.

Understanding Monoethanolamine: Properties and Common Uses

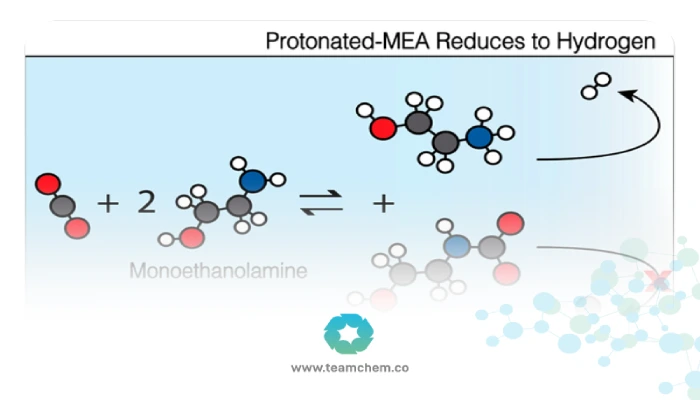

Monoethanolamine, chemically known as 2-aminoethanol or mono ethanol amine mea, is a colorless, viscous liquid with a mild ammonia-like odor. Its molecular formula, C₂H₇NO, classifies it as an alkanolamine—a hybrid of alcohol and amine functionalities—making it highly reactive and soluble in water. With a boiling point of 170°C and a flash point of 85°C, MEA is combustible but not highly flammable under normal conditions. Its density of 1.01 g/cm³ at 20°C and pH of 12.3 in 10% aqueous solution highlight its alkaline nature, which contributes to its utility in neutralizing acidic gases.

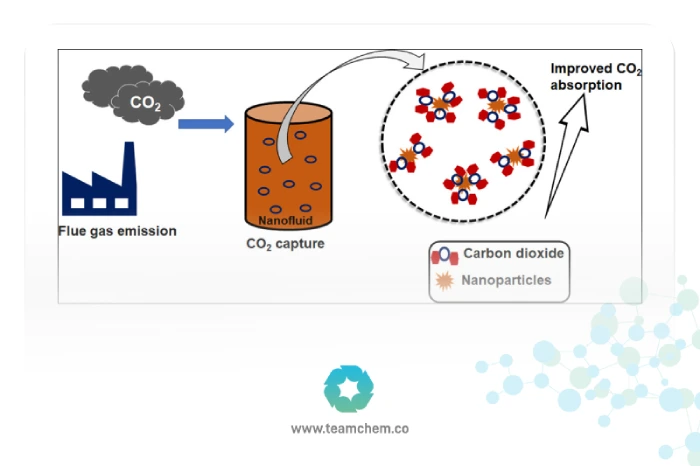

In industrial settings, MEA is predominantly used in gas sweetening processes, where it absorbs hydrogen sulfide (H₂S) and carbon dioxide (CO₂) from natural gas streams, preventing corrosion in pipelines. According to the American Petroleum Institute (API), MEA-based solutions are integral to over 70% of amine gas treatment units worldwide. Beyond oil and gas, MEA serves as a pH adjuster in cosmetics, a surfactant in detergents, and a building block for herbicides and pharmaceuticals. At TeamChem, our MEA is sourced from ISO-certified manufacturers, ensuring 99% purity to minimize impurities that could exacerbate handling risks.

Health Hazards Associated with Monoethanolamine Exposure

Exposure to MEA poses significant health risks, primarily due to its corrosive and irritant properties. Direct contact with skin or eyes can cause severe burns, redness, and blistering, as the compound's high pH disrupts cellular membranes. Inhalation of vapors—especially in concentrations exceeding 3 ppm (the OSHA PEL)—may lead to respiratory tract irritation, coughing, shortness of breath, and in extreme cases, pulmonary edema. Ingestion, though rare, results in severe gastrointestinal damage, nausea, and potential perforation of the esophagus.

Long-term exposure studies, such as those from the National Institute for Occupational Safety and Health (NIOSH), indicate that chronic dermal contact can sensitize the skin, leading to allergic dermatitis in 5-10% of workers. Reproductive toxicity is low, but MEA is classified as a possible carcinogen (Group 2B by IARC) based on limited animal data showing bladder tumors at high doses. Vulnerable populations, including pregnant workers or those with pre-existing respiratory conditions, require extra caution.

Fire and Explosion Hazards: Mitigating Combustible Risks

Though not as volatile as hydrocarbons, MEA's flash point of 85°C classifies it as a Category 3 combustible liquid under NFPA 30. Fires involving MEA can release toxic fumes like nitrogen oxides and ammonia, exacerbating smoke inhalation risks. Autoignition occurs at 410°C, and it is incompatible with strong oxidizers (e.g., peroxides), acids, or copper alloys, which can generate heat or flammable hydrogen gas.

Preventive measures include grounding all transfer equipment to prevent static discharge and using explosion-proof ventilation in storage areas. In case of fire, water spray is effective for cooling but not for extinguishing—foam or dry chemical agents are preferred to avoid runoff contamination. TeamChem's MEA is stabilized with corrosion inhibitors to reduce reactivity, but users must still conduct compatibility tests before mixing with other chemicals.

Environmental Impact and Spill Prevention Strategies

MEA's high water solubility (infinite miscibility) makes spills a significant environmental concern, as it can contaminate groundwater and aquatic ecosystems. With an LD50 (fish) of 170 mg/L, it is moderately toxic to marine life, potentially disrupting pH balances in rivers or treatment plants. Chronic exposure in soil can inhibit microbial activity, affecting agriculture.

To mitigate, secondary containment bunds (110% of tank capacity) and spill kits with absorbent booms are essential. Neutralization with dilute acetic acid (to pH 7) before disposal follows RCRA guidelines. TeamChem advocates for zero-discharge policies, recycling MEA solutions where possible to reduce ecological footprints.

In oilfield applications, where MEA pairs with desiccants like calcium chloride for brine formulations, spill protocols must account for synergistic effects—ensuring no cross-contamination that could amplify runoff hazards.

Personal Protective Equipment: Essential Gear for Safe Handling

PPE is non-negotiable when working with MEA. Skin protection starts with chemical-resistant gloves (neoprene or nitrile, 15 mil thickness) and full-body suits of PVC or Tychem® to prevent permeation. For eyes, ANSI Z87.1-approved goggles with side shields or face shields are mandatory during transfers.

Respiratory protection requires NIOSH-approved half-face respirators with organic vapor cartridges for concentrations up to 10x PEL; supplied-air systems for higher levels. Footwear should be steel-toed boots with chemical soles, and donning a full-body apron during bulk handling adds an extra layer.

Training on PPE don/doff procedures is crucial—contaminated gear must be decontaminated with 5% vinegar solution before removal. At TeamChem, we bundle MEA orders with PPE checklists, ensuring compliance with 29 CFR 1910.132.

Safe Handling Procedures: Step-by-Step Best Practices

Handling MEA demands precision. Always work in well-ventilated areas (minimum 10 air changes/hour) to dilute vapors below 3 ppm. Use mechanical pumps for transfers, avoiding manual pouring to minimize splash risks. Label all containers with GHS pictograms: corrosive (GHS05) and exclamation mark (GHS07).

Hygiene protocols include prohibiting eating/drinking in handling zones and mandating handwashing with pH-neutral soap post-exposure. For loading/unloading, eye wash stations (15-minute flush capacity) and safety showers must be within 10 seconds' reach.

Storage and Transportation: Ensuring Stability and Compliance

Storage of MEA requires cool, dry conditions (below 40°C) in HDPE or stainless steel tanks with secondary containment. Avoid direct sunlight to prevent polymerization, and use nitrogen blanketing for long-term storage to inhibit oxidation. Shelf life is 2 years when properly sealed.

For transportation, MEA is UN 2491, Class 8 (corrosive), Packing Group III—requiring DOT-approved drums or IBCs with UN markings. Placards must display corrosive warnings, and drivers trained under HAZMAT regulations. Incompatible loads (e.g., acids) are prohibited.

TeamChem's logistics partners use GPS-tracked vehicles with spill response kits, ensuring 99.9% on-time delivery without incidents since 2015.

Emergency Response: First Aid and Incident Management

Immediate action is vital in MEA exposures. For skin contact, flush with lukewarm water for 20 minutes while removing contaminated clothing—do not neutralize on skin to avoid heat generation. Eye exposure demands irrigation with saline for at least 15 minutes, followed by medical evaluation.

Inhalation victims should be moved to fresh air; administer oxygen if breathing is labored, and monitor for pulmonary effects up to 48 hours. Ingestion requires no induced vomiting—dilute with milk or water (240 mL) and seek poison control.

Fire response involves evacuating upwind and using SCBA gear. TeamChem's emergency kits include neutralizing agents and provide 24/7 SDS access via our app.

Spill and Leak Management: Containment and Cleanup Protocols

Small spills (<1 L) can be absorbed with vermiculite or sand, then neutralized with citric acid solution before disposal as hazardous waste. Larger spills require diking to prevent spread, followed by vacuum recovery and professional remediation.

Post-cleanup, monitor air quality for residual vapors. In gas plants, where MEA leaks into triethylene glycol teg dehydration units, immediate shutdown and flushing are critical to avoid foaming issues.

TeamChem offers spill training webinars, helping clients achieve zero-reportable incidents.

Related Chemicals: Synergies and Safety Parallels

In the oil and gas sector, MEA often interfaces with desiccants like calcium chloride, which absorbs moisture in drilling fluids but requires separate handling to prevent exothermic reactions. Calcium Chloride, in flake or pellet form, complements MEA in completion fluids, yet its dust hazards necessitate dust masks—unlike MEA's vapor focus.

Similarly, triethylene glycol teg, used for gas dehydration, shares MEA's hygroscopic traits but poses lower corrosivity; both demand compatible piping to avoid degradation. Triazine biocides, employed in MEA solutions to control bacteria, introduce formaldehyde risks—requiring enhanced ventilation.

Gilsonite, a natural asphaltite additive in drilling muds, pairs with MEA in lost circulation control but its dust can irritate when mixed—highlighting the need for integrated SDS reviews. At TeamChem, we supply these as bundled kits with cross-compatibility matrices.

Regulatory Compliance: Navigating Global Standards

Compliance with GHS, REACH, and TSCA is mandatory for MEA handlers. Labeling must include signal words "DANGER" and hazard statements like H302 (harmful if swallowed) and H314 (causes severe skin burns). Record-keeping for exposures under OSHA 1910.1020 is essential.

In the EU, CLP regulations cap MEA in consumer products at 5%, while Iran's INSO standards align with ISO 14001 for environmental management. TeamChem's audit-ready documentation simplifies certification.

Training and Education: Building a Safety Culture

Effective safety hinges on training. Annual refreshers on MEA hazards, using simulations, boost retention by 60% (per DuPont studies). TeamChem's e-learning modules cover MEA-specific scenarios, from lab spills to plant evacuations.

Fostering a just culture—reporting near-misses without blame—reduces incidents by 50%. Our partnerships with NIOSH-accredited centers ensure up-to-date curricula.

Case Studies: Lessons from Real-World Incidents

The 2010 MEA release in a Norwegian gas plant, causing 12 injuries from vapor exposure, highlighted ventilation failures—leading to retrofits that cut risks by 70%. Similarly, a U.S. detergent facility spill in 2018 underscored PPE lapses, resolved via TeamChem's rapid SDS delivery.

These cases reinforce proactive measures, saving costs—average MEA incident: $50,000 in medical/liability.

Technological Innovations in MEA Safety

Advances like IoT sensors for real-time vapor monitoring (detecting 1 ppm thresholds) and AI-driven predictive analytics for leak detection are transforming handling. Robotic transfer systems minimize human exposure, with TeamChem piloting these in client facilities.

Wearable dosimeters, integrating with apps, alert users to cumulative exposures, aligning with NIOSH's smart safety push.

Conclusion: Prioritizing Safety with TeamChem

Monoethanolamine remains indispensable, but its safe handling demands vigilance—from PPE to compliance. By adhering to these guidelines, you protect health, assets, and the environment. TeamChem is your partner in this journey, supplying pure MEA and expert support. Contact us today for a safety audit—empower your operations with confidence.

Frequently Asked Questions

1. What are the primary health hazards of exposure to mono ethanol amine mea, and how can they be prevented?

Mono ethanol amine mea is corrosive and irritant, causing skin/eye burns upon contact, respiratory irritation from vapors (>3 ppm), and potential long-term dermatitis or pulmonary edema. Prevention starts with PPE: nitrile gloves, face shields, and respirators with organic vapor cartridges. Maintain ventilation (10 air changes/hour) and limit exposure below OSHA PEL (3 ppm). At TeamChem, our high-purity mono ethanol amine mea includes exposure labels

2. How should spills of mono ethanol amine mea be managed to minimize environmental impact?

Contain small spills (<1 L) with absorbent booms like vermiculite, neutralize to pH 7 with dilute acetic acid, and dispose as hazardous waste per RCRA. For larger spills, dike and vacuum recover, avoiding runoff into waterways (MEA's LD50 for fish is 170 mg/L). Use secondary bunds (110% tank capacity

3. What PPE is essential for handling mono ethanol amine mea in industrial settings?

Essential gear includes neoprene gloves (15 mil), Tychem® suits, ANSI Z87.1 goggles, and NIOSH half-face respirators for vapors up to 10x PEL. Add steel-toed boots and aprons for bulk transfers. Decontaminate with 5% vinegar post-use. TeamChem's MEA kits include PPE checklists per 29 CFR 1910.132. When combining with Calcium Chloride in brines, add dust masks for the desiccant's hazards.

4. Are there fire risks with mono ethanol amine mea, and what extinguishing methods work best?

MEA is a Category 3 combustible (flash point 85°C), releasing toxic NOx/ammonia fumes in fires. Use foam or dry chemicals—avoid water streams to prevent spread. Ground equipment to eliminate static, and store below 40°C away from oxidizers. Autoignition at 410°C requires explosion-proof vents